Iimveliso

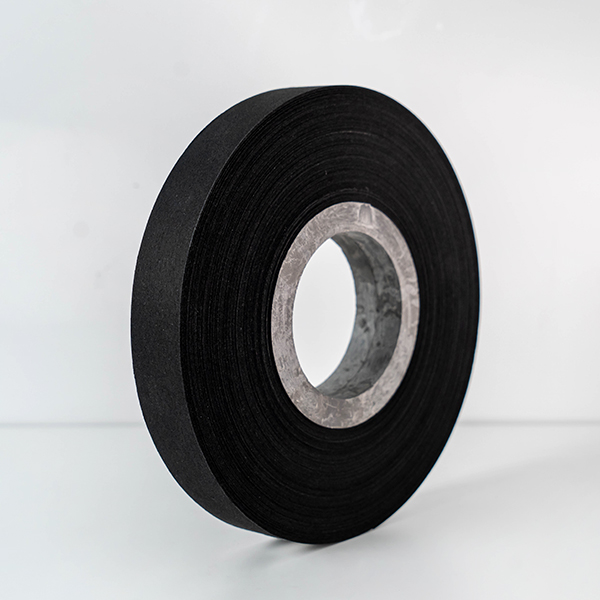

Iteyiphu yokuVimba amanzi eqhuba kancinci

Iteyiphu yokuVimba amanzi eqhuba kancinci

Intshayelelo yeMveliso

Iteyiphu yokuvimba amanzi ehambisa amanzi kancinci (okanye iteyiphu yokuvimba amanzi kancinci) sisixhobo sanamhlanje sokukhusela amanzi esinobuchwepheshe obuphezulu esinomsebenzi wokufunxa amanzi kancinci kunye nokwandisa (iteyiphu yokudumba), esenziwe ngelaphu elingalukwanga le-polyester fiber engahambisaniyo kancinci kunye ne-resin yokwandisa amanzi ngokukhawuleza.

Phakathi kwazo, umaleko wesiseko ohamba kancinci wenziwa ngokusasaza ngokulinganayo i-semi-conductive compound kwilaphu lesiseko elithe tyaba, elinokumelana nobushushu obuphezulu kunye namandla aphezulu; izinto ezithintela amanzi ezihamba kancinci zisebenzisa izinto ezifunxa amanzi zepolymer ezifunxayo kunye ne-conductive carbon black. Izinto ezifunxa amanzi zincamathiselwe kwilaphu lesiseko ngokugquma okanye ngokugquma.

Iteyiphu yokuthintela amanzi eqhuba kancinci inomsebenzi wokufunxa amanzi nokwandisa nokuphucula ukusasazwa kombane kwintambo, kwaye isetyenziswa kakhulu kwiintambo zamandla zamanqanaba ahlukeneyo ombane.

Singabonelela ngeteyiphu yokuvimba amanzi ecala elinye/ecala elinye. Iteyiphu yebloko yamanzi ecala elinye yenziwe ngomaleko omnye welaphu elingalukwanga le-polyester fiber eqhuba amanzi kunye ne-resin ekhulisa amanzi ngesantya esiphezulu; iteyiphu yokuvimba amanzi ecala elinye yenziwe ngelaphu elingalukwanga le-polyester fiber eqhuba amanzi, i-resin ekhulisa amanzi ngesantya esiphezulu kunye nelaphu elingalukwanga le-polyester fiber eqhuba amanzi ngesantya esiphezulu. Iteyiphu yebloko yamanzi ecala elinye isebenza ngcono kuba ayinalaphu elisisiseko lokuvimba.

iimpawu

Iteyiphu yokuthintela amanzi eqhuba kancinci esiyinikezileyo ineempawu ezilandelayo:

1) Umphezulu uthe tyaba, awunamibimbi.

2) Ifayibha isasazwa ngokulinganayo, umgubo ovimba amanzi kunye neteyiphu esisiseko zibotshelelwe ngokuqinileyo, ngaphandle kokususwa kwe-delamination kunye nokususwa komgubo.

3) Amandla aphezulu oomatshini, kulula ukuwasonga kunye nokuwasonga okude.

4) I-hygroscopicity enamandla, ukuphakama okuphezulu kokukhula, isantya sokwanda ngokukhawuleza, kunye nozinzo oluhle lwejeli.

5) Ukumelana okuncinci komphezulu kunye nokumelana nomthamo, okunokwenza buthathaka amandla ombane

6) Ukumelana nobushushu okuhle, ukumelana nobushushu obuphezulu ngoko nangoko, intambo inokugcina ukusebenza okuzinzileyo phantsi kobushushu obuphezulu ngoko nangoko.

7) Uzinzo oluphezulu lweekhemikhali, akukho zinto zibolayo, ziyamelana nokukhukuliseka kweebhaktiriya kunye nefungus.

Isicelo

Isetyenziswa kakhulu kwiintambo zombane zamanqanaba ahlukeneyo ombane ukuvala amanzi nokuphucula ukusasazwa kombane.

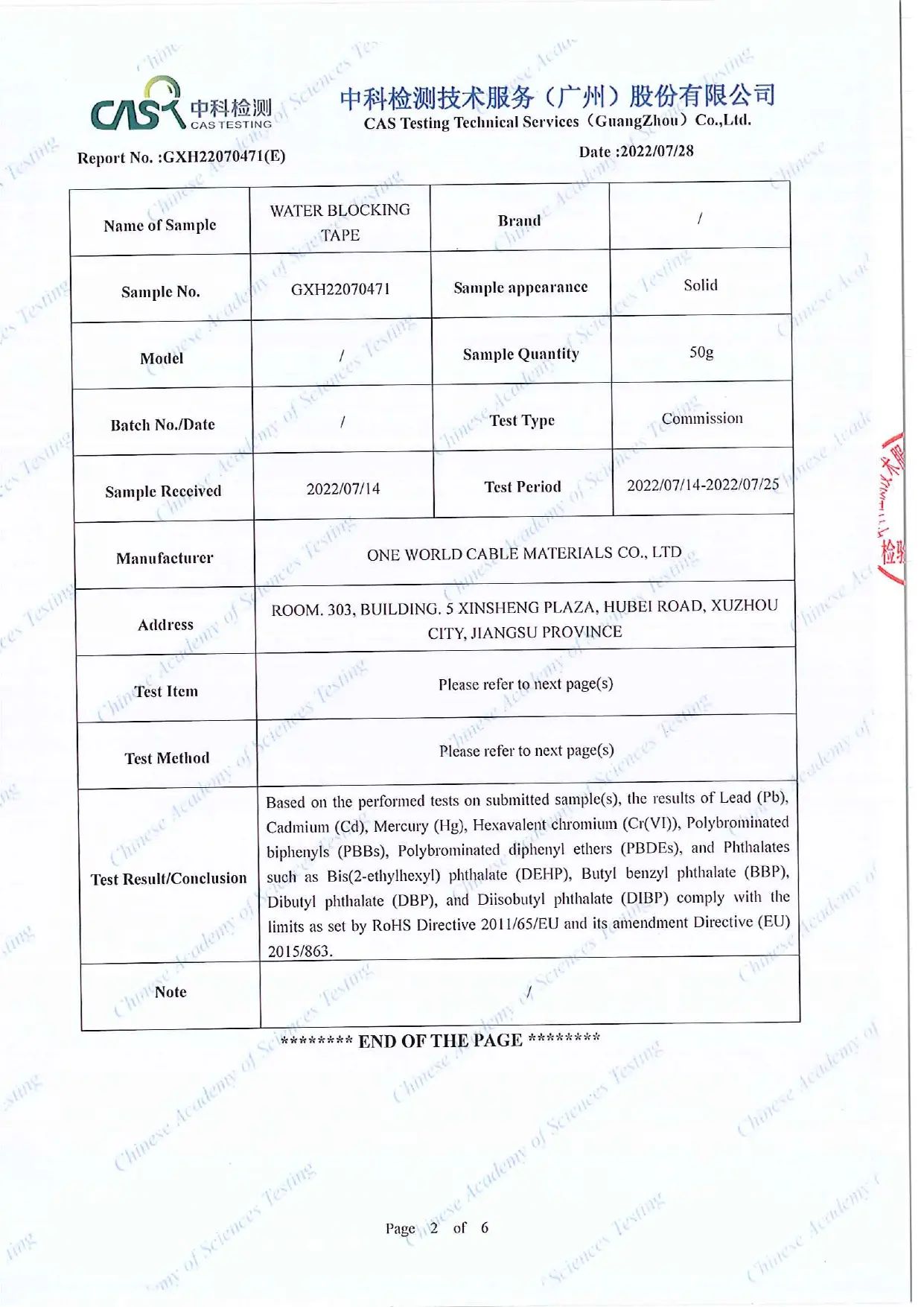

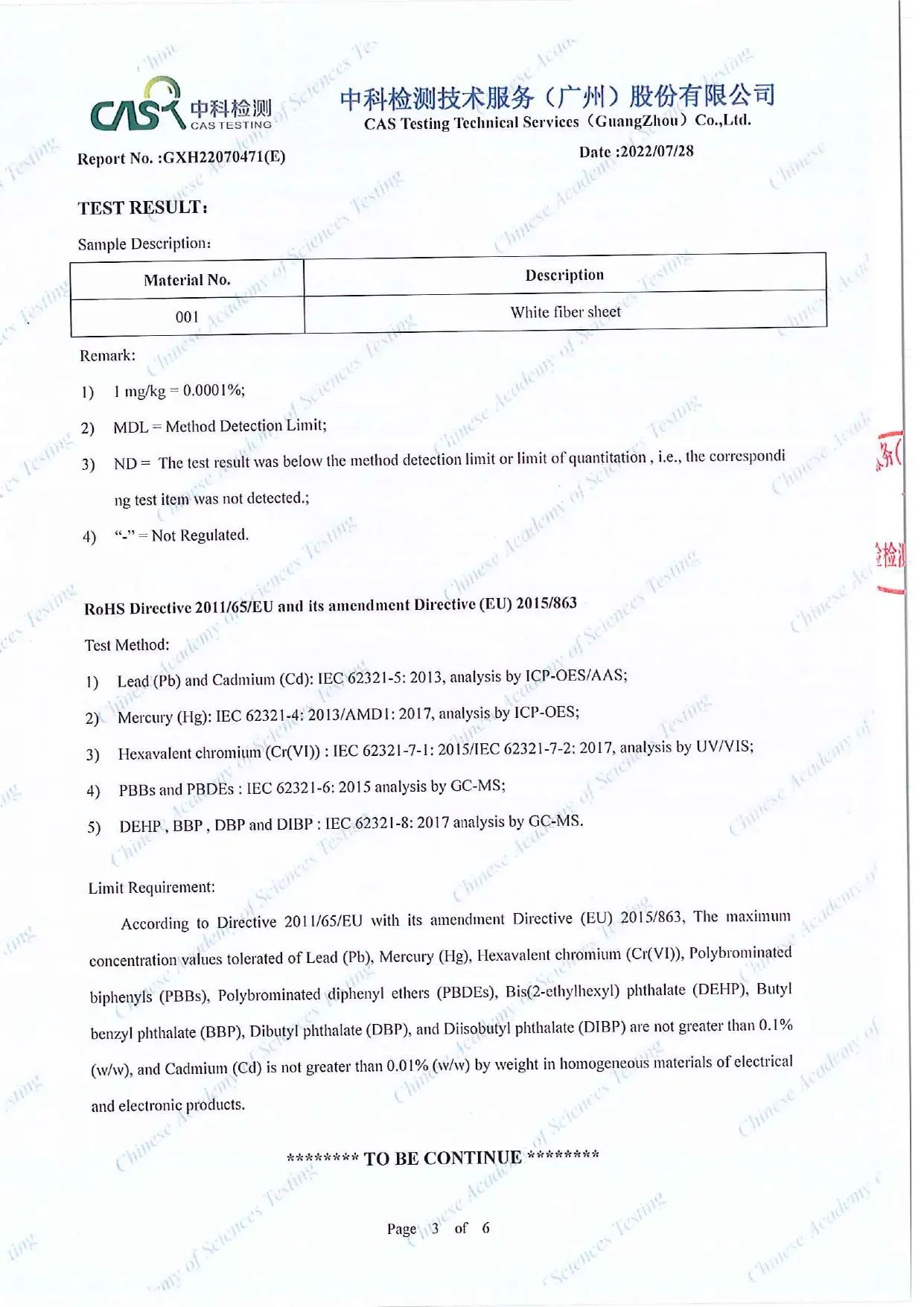

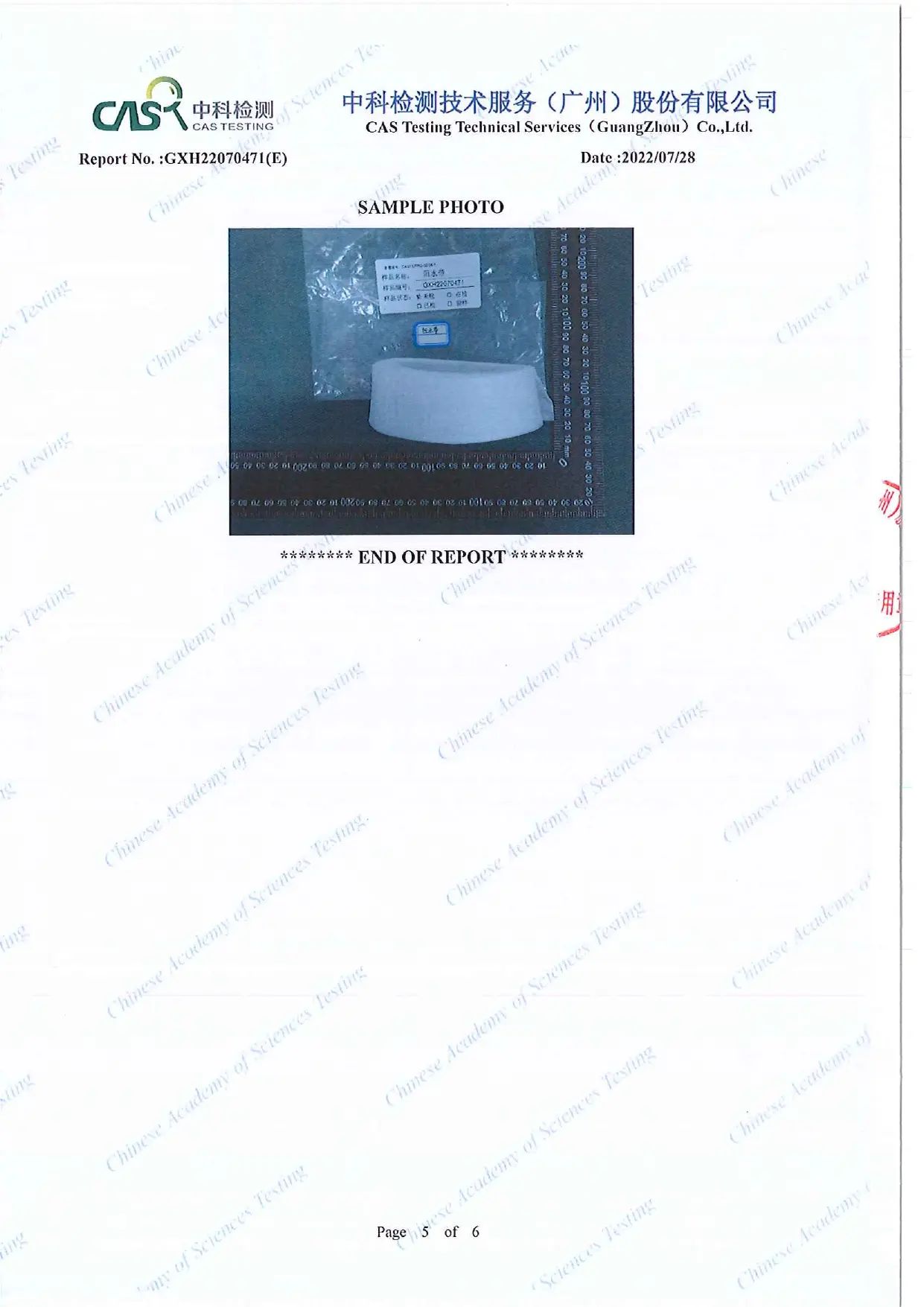

| Uzinzo lobushushu | |

| a) Ukumelana nobushushu bexesha elide (90℃, iiyure ezingama-24) Ukuphakama kokwandiswa (mm) | ≥Ixabiso lokuqala |

| b) Ubushushu obuphezulu obukhawulezileyo (230℃, 20s) Ukuphakama kokwandiswa (mm) | ≥Ixabiso lokuqala |

| Qaphela: Iinkcukacha ezingaphezulu, nceda unxibelelane nabasebenzi bethu bokuthengisa. | |

Iiparameters zobugcisa

| Into | Iiparameters zobugcisa | |||||

| Iteyiphu yokuthintela amanzi ethintela umqhubi wesiqingatha kwicala elinye | Iteyiphu yokuthintela amanzi ethintela umbane enamacala amabini | |||||

| Ubukhulu obuqhelekileyo (mm) | 0.3 | 0.4 | 0.5 | 0.3 | 0.4 | 0.5 |

| Amandla okuxinana (N/cm) | ≥30 | ≥30 | ≥40 | ≥30 | ≥30 | ≥40 |

| Ukuqhekeka kobude (%) | ≥10 | ≥10 | ≥10 | ≥10 | ≥10 | ≥10 |

| Ukumelana nomphezulu (Ω) | ≤1500 | ≤1500 | ≤1500 | ≤1500 | ≤1500 | ≤1500 |

| Ukumelana nomthamo (Ω·cm) | ≤1×105 | ≤1×105 | ≤1×105 | ≤1×105 | ≤1×105 | ≤1×105 |

| Isantya sokwandisa (mm/min) | ≥6 | ≥8 | ≥10 | ≥8 | ≥8 | ≥10 |

| Ukuphakama kokwandiswa (mm/5min) | ≥8 | ≥10 | ≥14 | ≥10 | ≥10 | ≥14 |

| Umlinganiselo wamanzi (%) | ≤9 | ≤9 | ≤9 | ≤9 | ≤9 | ≤9 |

Ukupakisha

Iphedi nganye yeteyiphu yokuthintela amanzi ehambisa amanzi kancinci ipakishwa kwingxowa yefilimu engangenisi manzi ngokwahlukeneyo, kwaye iiphedi ezininzi zisongelwa kwingxowa yefilimu enkulu engangenisi manzi, emva koko zipakishwe kwibhokisi, kwaye iibhokisi ezingama-20 zifakwa kwipheyile.

Ubungakanani bephakheji: 1.12m*1.12m*2.05m

Ubunzima obupheleleyo kwipallet nganye: malunga ne-780kg

Indawo yokugcina izinto

1) Imveliso mayigcinwe kwindawo yokugcina izinto ecocekileyo, eyomileyo nengena umoya.

2) Imveliso akufuneki ibekwe ndawonye neemveliso ezinokutsha okanye izinto ezinamandla zokuxovula kwaye akufuneki ibe kufutshane nemithombo yomlilo.

3) Imveliso mayiphephe ukukhanya kwelanga ngqo kunye nemvula.

4) Imveliso mayipakishwe ngokupheleleyo ukuze kuthintelwe ukufuma kunye nongcoliseko.

5) Imveliso mayikhuselwe kuxinzelelo olukhulu kunye neminye imonakalo yoomatshini ngexesha lokugcina.

6) Ixesha lokugcina imveliso kubushushu obuqhelekileyo ziinyanga ezi-6 ukusukela kumhla wokuveliswa. Ixesha lokugcina imveliso lingaphezulu kweenyanga ezi-6, kufuneka iphinde ihlolwe kwaye isetyenziswe kuphela emva kokudlula uvavanyo.

Isiqinisekiso

IMIQATHANGO YESAMPULE YASIMAHLA

I-ONE WORLD izibophelele ekuboneleleni abathengi ngezixhobo zobugcisa ezikumgangatho ophezulu kunye neentambo kunye neenkonzo zobugcisa zeklasi yokuqala.

Ungacela Isampulu Yasimahla Yemveliso Onomdla Kuyo, Oko Kuthetha Ukuba Uzimisele Ukusebenzisa Imveliso Yethu Kwimveliso

Sisebenzisa kuphela idatha yovavanyo ozimisele ukuyinika impendulo kwaye wabelane ngayo njengoqinisekiso lweempawu zemveliso kunye nomgangatho, size sincede ekusekeni inkqubo epheleleyo yokulawula umgangatho ukuphucula ukuthembana kwabathengi kunye nenjongo yokuthenga, ngoko ke nceda uqinisekise.

Ungazalisa ifomu ekunene yokucela isampuli yasimahla

Imiyalelo yesicelo

1. Umthengi uneAkhawunti yokuhanjiswa kwempahla ye-International Express ehlawula ngokuzithandela impahla (impahla ingabuyiselwa nge-odolo)

2. Eli ziko linye linokufaka isicelo sesampuli enye yasimahla yemveliso enye, kwaye eli ziko linye linokufaka isicelo seesampuli ezintlanu zeemveliso ezahlukeneyo simahla kungekapheli nonyaka omnye.

3. Isampulu Yeyabathengi BeeNtambo NeeCable Fektri Kuphela, Kwaye Yeyabasebenzi Beelebhu Kuphela Bovavanyo Lwemveliso Okanye Uphando

IPAKETHE YESAMPULE

IFOMU YESICELO SESAMPULE YASIMAHLA

Nceda ufake iinkcukacha zesampulu ezifunekayo, okanye uchaze ngokufutshane iimfuno zeprojekthi, siza kukucebisa iisampulu.

Emva kokungenisa ifomu, ulwazi oluzalisayo lungadluliselwa kwi-ONE WORLD background ukuze luqwalaselwe ngakumbi ukuze kuchongwe iinkcukacha zemveliso kunye nolwazi lwedilesi nawe. Kwaye singaqhagamshelana nawe ngefowuni. Nceda ufunde eyethuUmthetho wabucalaUkuze ufumane iinkcukacha ezithe vetshe.