1. Isishwankathelo

Ngenxa yophuhliso olukhawulezileyo lwetekhnoloji yolwazi nonxibelelwano, iintambo ze-optical, njengeyona nto iphambili yokuhambisa ulwazi lwanamhlanje, zinemfuno ephezulu yokusebenza kunye nomgangatho.I-Polybutylene terephthalate (PBT), njengeplastiki yobunjineli be-thermoplastic enentsebenzo egqwesileyo, idlala indima ebalulekileyo ekuvelisweni kweentambo ze-optical. I-PBT yenziwa yi-condensation polymerization ye-dimethyl terephthalate (DMT) okanye i-terephthalic acid (TPA) kunye ne-butanediol emva kwe-esterification. Yenye yeeplastiki ezintlanu zobunjineli ezisetyenziswa ngokubanzi kwaye yaqalwa yaphuhliswa yi-GE kwaye yaphuhliswa ngeminyaka yoo-1970. Nangona yaqala emva kwexesha elithile, iphuhliswe ngokukhawuleza kakhulu. Ngenxa yokusebenza kwayo okugqwesileyo, ukuqhubekeka kwayo okunamandla kunye nokusebenza okubiza kakhulu, isetyenziswa kakhulu kwizixhobo zombane, iimoto, unxibelelwano, izixhobo zasekhaya nakwamanye amacandelo. Ingakumbi ekuvelisweni kweentambo ze-optical, isetyenziswa kakhulu ekuvelisweni kweetyhubhu ezikhululekileyo zefayibha ye-optical kwaye luhlobo oluyimfuneko lwezinto zentambo ezisebenza kakhulu kwizixhobo eziluhlaza zeentambo ze-optical.

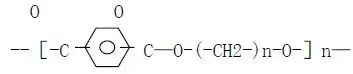

I-PBT yi-polyester emhlophe efana nobisi ecacileyo ukuya kwi-semi-crystalline engabonakaliyo enokumelana nobushushu obuhle kakhulu kunye nokuzinza kokucubungula. Ulwakhiwo lwayo lwe-molecular yi-[(CH₂)₄OOCC₆H₄COO]n. Xa ithelekiswa ne-PET, inamaqela amabini e-methylene kwi-chain segments, nto leyo enika i-molecule chain yayo ephambili isakhiwo esijikelezayo kunye nokuguquguquka okungcono. I-PBT ayixhathisi kwi-acids ezinamandla kunye ne-alkalis ezinamandla, kodwa inokumelana ne-organic solvents ezininzi kwaye iya kubola kumaqondo obushushu aphezulu. Ngenxa yeempawu zayo ezintle zomzimba, ukuzinza kweekhemikhali kunye nokusebenza kokucubungula, i-PBT ibe yinto efanelekileyo yokwakha kwishishini le-optical cable kwaye isetyenziswa kakhulu kwiimveliso ezahlukeneyo ze-PBT kwiintambo zonxibelelwano kunye neentambo ze-optical.

2. Iimpawu zezinto zePBT

I-PBT idla ngokusetyenziswa ngendlela yemixube eguquliweyo. Ngokongeza izinto ezithintela ilangatye, izinto zokuqinisa kunye nezinye iindlela zokuguqula, ukumelana kwayo nobushushu, ubushushu bombane kunye nokuguquguquka kokucubungula kunokuphuculwa ngakumbi. I-PBT inamandla aphezulu oomatshini, ukuqina okuhle kunye nokumelana nokuguguleka, kwaye inokukhusela ngokufanelekileyo imicu ye-optical ngaphakathi kwintambo ye-optical kumonakalo woxinzelelo loomatshini. Njengenye yezinto eziqhelekileyo ezisetyenziswa kwiintambo ze-optical, i-resin ye-PBT iqinisekisa ukuba iimveliso zentambo ye-optical zinokuguquguquka okuhle kunye nozinzo ngelixa zigcina amandla olwakhiwo.

Okwangoku, inamandla okuqina kweekhemikhali kwaye inokumelana neendlela ezahlukeneyo zokubola, iqinisekisa ukusebenza okuzinzileyo kwexesha elide kweentambo ze-optical kwiindawo ezinzima ezifana nokufuma kunye ne-salt spray. Izinto ze-PBT zinozinzo oluhle kakhulu lobushushu kwaye zinokugcina ukusebenza okuzinzileyo nakwiindawo ezinobushushu obuphezulu, okwenza ukuba zifaneleke ukusetyenziswa kweentambo ze-optical kwiindawo ezahlukeneyo zobushushu. Isebenza kakuhle kakhulu ekucubunguleni kwaye inokwenziwa nge-extrusion, i-injection molding kunye nezinye iindlela. Ifanelekile kwiindibano zeentambo ze-optical zeemilo ezahlukeneyo kunye nezakhiwo kwaye yiplastiki yobunjineli esebenza kakhulu esetyenziswa kakhulu ekuveliseni iintambo.

3. Ukusetyenziswa kwe-PBT kwiintambo ze-Optical

Kwinkqubo yokwenziwa kweentambo ze-optical, i-PBT isetyenziswa kakhulu ekuveliseni iityhubhu ezikhululekileyoiifayibha ezibonakalayoAmandla ayo aphezulu kunye nokuqina kwayo kunokuxhasa ngempumelelo nokukhusela iifayibha ze-optical, kuthintela umonakalo obangelwa zizinto ezibonakalayo ezifana nokugoba kunye nokwelula. Ukongeza, izinto ze-PBT zinokumelana okuhle kobushushu kunye nokusebenza okuchasene nokwaluphala, okunceda ukuphucula uzinzo kunye nokuthembeka kweentambo ze-optical ngexesha lokusebenza ixesha elide. Yenye yezinto eziphambili ze-PBT ezisetyenziswa kwiintambo ze-optical okwangoku.

I-PBT ikwasetyenziswa rhoqo njengesigqubuthelo sangaphandle seentambo ze-optical. Isigqubuthelo asidingi nje kuphela ukuba namandla athile oomatshini ukuze sikwazi ukumelana notshintsho kwimeko-bume yangaphandle, kodwa kufuneka sibe nokumelana okuhle kokuguguleka, ukumelana nokugqwala kweekhemikhali kunye nokumelana nokuguga kwe-UV ukuqinisekisa ubomi benkonzo yentambo ye-optical ngexesha lokubekwa ngaphandle, kwiindawo ezimanzi okanye zaseLwandle. Isigqubuthelo sentambo ye-optical sineemfuno eziphezulu zokusebenza kokucubungula kunye nokuzivumelanisa nokusingqongileyo kwe-PBT, kwaye i-resin ye-PBT ibonisa ukuhambelana okuhle kokusetyenziswa.

Kwiinkqubo zokudibanisa iintambo ze-optical, i-PBT ingasetyenziselwa ukuvelisa izinto ezibalulekileyo ezifana neebhokisi zokudibanisa. Ezi zinto kufuneka zihlangabezane neemfuno ezingqongqo zokuvala, ukuthintela amanzi kunye nokumelana nemozulu. Izinto ze-PBT, ezineempawu zazo zomzimba ezintle kunye nozinzo lwesakhiwo, lukhetho olufanelekileyo kakhulu kwaye zidlala indima ebalulekileyo yokuxhasa isakhiwo kwinkqubo yezinto ezikrwada zentambo ze-optical.

4. Amanyathelo okukhusela

Ngaphambi kokuba kuqhutywe i-injection molding, i-PBT kufuneka yomiswe kwi-110℃ ukuya kwi-120℃ kangangeeyure ezi-3 ukuze kususwe umswakama ofunxiweyo kwaye kuthintelwe ukwakheka kwamaqamza okanye ukubhitya ngexesha lokucubungula. Ubushushu bokubumba kufuneka bulawulwe phakathi kwe-250℃ kunye ne-270℃, kwaye ubushushu bokubumba bucetyiswa ukuba bugcinwe kwi-50℃ ukuya kwi-75℃. Ngenxa yokuba ubushushu bokutshintsha kweglasi ye-PBT buyi-22℃ kuphela kwaye izinga lokupholisa i-crystallization likhawuleza, ixesha layo lokupholisa lifutshane. Ngexesha lenkqubo yokubumba i-injection, kuyimfuneko ukuthintela ubushushu be-nozzle ukuba bungabi phantsi kakhulu, nto leyo enokubangela ukuba umjelo wokuhamba uvalwe. Ukuba ubushushu be-barrel budlula i-275℃ okanye izinto ezinyibilikisiweyo zihlala ixesha elide kakhulu, zinokubangela ukuwohloka kobushushu kunye nokuqhekeka.

Kucetyiswa ukuba kusetyenziswe isango elikhulu xa kujovwa. Inkqubo ye-hot runner akufuneki isetyenziswe. Isikhunta kufuneka sigcine isiphumo esihle sokukhupha umoya. Izinto ze-PBT sprue eziqulethe izinto ezithintela ilangatye okanye ukuqinisa ifayibha yeglasi azikhuthazwa ukuba zisetyenziswe kwakhona ukuze kuthintelwe ukuwohloka kokusebenza. Xa umatshini uvaliwe, umgqomo kufuneka ucocwe ngexesha kunye nezinto ze-PE okanye ze-PP ukuthintela ukufakwa kwekhabhoni kwezinto eziseleyo. Ezi paramitha zokucubungula zinokubaluleka okusebenzayo kubavelisi bezinto ezikrwada zekhebula le-optical kwimveliso enkulu yezinto zekhebula.

5. Iingenelo zeSicelo

Ukusetyenziswa kwe-PBT kwiintambo ze-optical kuphucule kakhulu ukusebenza kweentambo ze-optical. Amandla ayo aphezulu kunye nokuqina kwayo kuphucula ukumelana nempembelelo kunye nokumelana nokudinwa kwentambo ye-optical, kwaye kwandisa ubomi bayo benkonzo. Okwangoku, ukuqhubekeka kakuhle kwezixhobo ze-PBT kuphucule ukusebenza kakuhle kwemveliso kwaye kunciphisa iindleko zokuvelisa. Ukumelana okuhle kakhulu nokungaluphali kunye nokugqwala kweekhemikhali kwentambo ye-optical kuyenza ikwazi ukugcina ukusebenza okuzinzileyo ixesha elide kwiindawo ezinzima, okuphucula kakhulu ukuthembeka kunye nomjikelo wokugcinwa kwemveliso.

Njengoluhlu oluphambili kwizinto ezisetyenziswa kwiintambo ze-optical, i-PBT resin idlala indima kwiikhonkco ezininzi zesakhiwo kwaye yenye yeeplastiki zobunjineli be-thermoplastic ezinikwa kuqala ngabavelisi beentambo ze-optical xa bekhetha izixhobo zentambo.

6. Izigqibo kunye namathemba

I-PBT ibe yinto ebalulekileyo kakhulu kwicandelo lokwenziwa kweentambo ze-optical ngenxa yokusebenza kwayo okugqwesileyo kwiipropati zoomatshini, uzinzo lobushushu, ukumelana nokugqwala kunye nokuqhubekeka kokusebenza. Kwixesha elizayo, njengoko ishishini lonxibelelwano lwe-optical liqhubeka nokuphucula, iimfuno eziphezulu ziya kubekwa phambili ekusebenzeni kwezinto. Ishishini le-PBT kufuneka liqhubeke nokukhuthaza ubuchule bobuchwephesha kunye nophuhliso lokhuseleko lokusingqongileyo oluluhlaza, liphucula ngakumbi ukusebenza kwalo okubanzi kunye nokusebenza kakuhle kwemveliso. Ngelixa lihlangabezana neemfuno zokusebenza, ukunciphisa ukusetyenziswa kwamandla kunye neendleko zezinto kuya kunceda i-PBT idlale indima ebaluleke ngakumbi kwiintambo ze-optical kunye noluhlu olubanzi lweendawo zesicelo.

Ixesha lokuthumela: Juni-30-2025