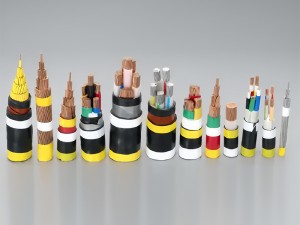

Ulwakhiwo lwentambo lubonakala lulula, eneneni, inxalenye nganye yayo inenjongo yayo ebalulekileyo, ngoko ke izinto zenxalenye nganye kufuneka zikhethwe ngononophelo xa kusenziwa intambo, ukuze kuqinisekiswe ukuthembeka kwentambo eyenziwe ngezi zinto ngexesha lokusebenza.

1. Izinto zomqhubi

Ngokwembali, izinto ezisetyenziselwa abaqhubi beentambo zombane yayiziithusi kunye ne-aluminium. I-sodium nayo yazanywa okwethutyana. I-Copper kunye ne-aluminium zinombane ongcono, kwaye ubungakanani be-copper buncinci xa kuthunyelwa umbane ofanayo, ngoko ke ububanzi bangaphandle bomqhubi we-copper buncinci kunobomqhubi we-aluminium. Ixabiso le-aluminium liphantsi kakhulu kunobhedu. Ukongeza, kuba ubuninzi be-copper bukhulu kunobo be-aluminium, nokuba amandla okuthwala umbane afana, icandelo elinqamlezileyo lomqhubi we-aluminium likhulu kunomqhubi we-copper, kodwa i-aluminium conductor cable isalula kune-copper conductor cable.

2. Izixhobo zokuvala ubushushu

Kukho izinto ezininzi zokukhusela ezinokusetyenziswa ziintambo zombane zeMV, kuquka nezinto zokukhusela iphepha ezivuthwe ngobuchwepheshe, ezisetyenziswe ngempumelelo kangangeminyaka engaphezu kwe-100. Namhlanje, ukhuseleko lwepolymer olukhutshweyo luye lwamkelwe ngokubanzi. Izinto zokukhusela ipolymer ezikhutshweyo ziquka i-PE (LDPE kunye ne-HDPE), i-XLPE, i-WTR-XLPE kunye ne-EPR. Ezi zinto ziyi-thermoplastic kunye ne-thermosetting. Izinto ze-thermoplastic ziyaguquka xa zishushu, ngelixa izinto ze-thermoset zigcina imo yazo kumaqondo obushushu okusebenza.

2.1. Ukuthintela amaphepha

Ekuqaleni kokusebenza kwazo, iintambo ezifakwe ephepheni zithwala umthwalo omncinci kuphela kwaye zigcinwa kakuhle. Nangona kunjalo, abasebenzisi bamandla bayaqhubeka nokwenza intambo ethwala umthwalo ophezulu ngakumbi, iimeko zokuqala zokusetyenziswa azisafanelekanga kwiimfuno zentambo yangoku, ngoko amava amahle okuqala awanakumela ukusebenza kwexesha elizayo kwentambo kufuneka kube kuhle. Kwiminyaka yakutshanje, iintambo ezifakwe ephepheni azisetyenziswa rhoqo.

2.2.I-PVC

I-PVC isasetyenziswa njengesixhobo sokukhusela iintambo ze-1kV ezine-voltage ephantsi kwaye ikwayinto yokukhusela. Nangona kunjalo, ukusetyenziswa kwe-PVC kwi-cable insulation kutshintshwa ngokukhawuleza yi-XLPE, kwaye ukusetyenziswa kwi-sheath kutshintshwa ngokukhawuleza yi-linear low density polyethylene (LLDPE), i-medium density polyethylene (MDPE) okanye i-high density polyethylene (HDPE), kwaye iintambo ezingezizo ze-PVC zineendleko eziphantsi zomjikelo wobomi.

2.3. I-Polyethylene (PE)

I-polyethylene ephantsi (LDPE) yaphuhliswa ngeminyaka yoo-1930 kwaye ngoku isetyenziswa njenge-resin esisiseko yezinto ezidityanisiweyo ze-polyethylene (XLPE) kunye ne-polyethylene edityanisiweyo yemithi engangeni manzi (WTR-XLPE). Kwimeko ye-thermoplastic, ubushushu obuphezulu bokusebenza be-polyethylene yi-75 ° C, obuphantsi kunobushushu bokusebenza beentambo ezifakwe kwi-paper insulation (80 ~ 90 ° C). Le ngxaki isonjululwe ngokufika kwe-polyethylene edityanisiweyo (XLPE), enokufikelela okanye idlule ubushushu benkonzo yeentambo ezifakwe kwi-paper insulation.

2.4.I-polyethylene edityanisiweyo (XLPE)

I-XLPE yinto yokulungisa ubushushu eyenziwe ngokuxuba i-polyethylene ephantsi (i-LDPE) kunye ne-arhente yokudibanisa (efana ne-peroxide).

Ubushushu obuphezulu bokuqhuba intambo ye-XLPE egqunyiweyo yi-90 ° C, uvavanyo lokugqithisa lufikelela kwi-140 ° C, kwaye ubushushu be-short-circuit bunokufikelela kwi-250 ° C. I-XLPE ineempawu ezibalaseleyo ze-dielectric kwaye ingasetyenziswa kuluhlu lwe-voltage oluqala kwi-600V ukuya kwi-500kV.

2.5. Umthi ongangeni manzi I-polyethylene edibeneyo (WTR-XLPE)

Ingxaki yemithi yamanzi iya kunciphisa ubomi benkonzo yekhebula le-XLPE. Zininzi iindlela zokunciphisa ukukhula kwemithi yamanzi, kodwa enye yezona zamkelekileyo kukusebenzisa izixhobo zokukhusela ezenziwe ngobunjineli obukhethekileyo ezenzelwe ukuthintela ukukhula kwemithi yamanzi, ezibizwa ngokuba yi-water-resistant tree cross-linked polyethylene WTR-XLPE.

2.6. Irabha ye-ethylene propylene (EPR)

I-EPR yinto yokulungisa ubushushu eyenziwe nge-ethylene, i-propylene (ngamanye amaxesha i-monomer yesithathu), kwaye i-copolymer yee-monomers ezintathu ibizwa ngokuba yi-ethylene propylene diene rubber (EPDM). Kumaqondo obushushu abanzi, i-EPR ihlala ithambile kwaye inokumelana okuhle kwe-corona. Nangona kunjalo, ukulahleka kwe-dielectric kwezinto ze-EPR kuphezulu kakhulu kune-XLPE kunye ne-WTR-XLPE.

3. Inkqubo yokukhusela ubushushu

Inkqubo yokudibanisa ixhomekeke kwi-polymer esetyenzisiweyo. Ukwenziwa kwee-polymers ezidibeneyo kuqala nge-matrix polymer kwaye emva koko izibambi kunye nee-crosslinkers zongezwa ukwenza umxube. Inkqubo yokudibanisa idibanisa iindawo ezininzi zokudibanisa kwisakhiwo se-molecular. Nje ukuba idityaniswe, ikhonkco le-molecular ye-polymer lihlala lithambile, kodwa alinakuqhekeka ngokupheleleyo libe yi-fluid melt.

4. Izixhobo zokukhusela kunye nokukhusela umqhubi

Umaleko wokukhusela oqhuba kancinci ukhutshelwa ngaphandle komphezulu womqhubi kunye nobushushu ukuze ulingane intsimi yombane kwaye ubambe intsimi yombane kwisiseko esigqunywe yintambo. Le nto iqulethe umgangatho wobunjineli wezinto ezimnyama zekhabhoni ukuvumela umaleko wokukhusela wentambo ukuba ufezekise umbane ozinzileyo ngaphakathi koluhlu olufunekayo.

Ixesha lokuthumela: Epreli-12-2024