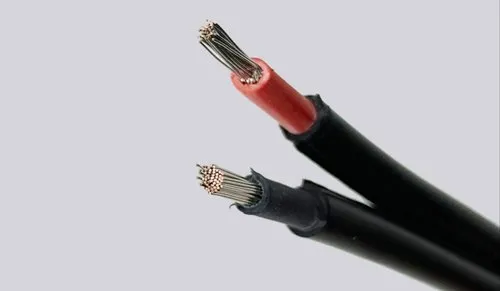

Okwangoku, isetyenziswa kakhuluizixhobo zokwambathisaKwi-DC cables yi-polyethylene. Nangona kunjalo, abaphandi bahlala befuna ezinye izinto zokukhusela ubushushu, ezifana ne-polypropylene (PP). Nangona kunjalo, ukusebenzisa i-PP njengesixhobo sokukhusela ubushushu bentambo kuzisa iingxaki ezininzi.

1. Iipropati zoomatshini

Ukuze kuhlangatyezwane neemfuno ezisisiseko zokuthutha, ukufakela, kunye nokusebenza kweentambo ze-DC, izinto zokukhusela kufuneka zibe namandla athile oomatshini, kubandakanya ukuguquguquka okuhle, ukunwebeka xa kuqhekeka, kunye nokumelana nempembelelo kubushushu obuphantsi. Nangona kunjalo, i-PP, njenge-polymer ekristale kakhulu, ibonisa ukuqina ngaphakathi komgangatho wayo wobushushu bokusebenza. Ukongeza, ibonisa ukubuthathaka kunye nokuqhekeka kwiindawo ezinobushushu obuphantsi, ingaphumeleli ukuhlangabezana nezi meko. Ke ngoko, uphando kufuneka lugxile ekuqiniseni nasekuguquleni i-PP ukuze kujongwane nale micimbi.

2. Ukumelana nokwaluphala

Ngexesha lokusetyenziswa ixesha elide, ukufakelwa kwentambo ye-DC kuyaguga kancinci kancinci ngenxa yeziphumo ezidibeneyo zokuqina okuphezulu kwamandla ombane kunye nokujikeleza kobushushu. Oku kuguga kukhokelela ekunciphiseni iimpawu zoomatshini kunye nokufakelwa, kunye nokuncipha kwamandla okuqhekeka, ekugqibeleni kuchaphazela ukuthembeka kunye nobomi benkonzo yentambo. Ukuguga kwentambo kubandakanya imiba yoomatshini, yombane, yobushushu, kunye neyekhemikhali, kunye nokuguga kombane kunye nobushushu kuyeyona nto ixhalabisayo. Nangona ukongeza ii-antioxidants kunokuphucula ukumelana kwe-PP nokuguga kwe-oxidative kobushushu kwinqanaba elithile, ukuhambelana okungahambi kakuhle phakathi kwee-antioxidants kunye ne-PP, ukufuduka, kunye nokungcola kwazo njengezongezo kuchaphazela ukusebenza kwe-insulation ye-PP. Ke ngoko, ukuthembela kuphela kwii-antioxidants ukuphucula ukumelana nokuguga kwe-PP akunakuhlangabezana neemfuno zobomi kunye nokuthembeka kwe-insulation yentambo ye-DC, nto leyo edinga uphando olongezelelweyo malunga nokuguqula i-PP.

3. Ukusebenza kobushushu

Umbane wendawo, njengenye yezinto ezichaphazela umgangatho kunye nobomi bexeshaiintambo zeDC ezine-voltage ephezulu, inefuthe elikhulu ekusasazweni kwentsimi yombane yasekuhlaleni, amandla e-dielectric, kunye nokuguga kwezinto zokwambathisa. Izixhobo zokwambathisa iintambo ze-DC kufuneka zithintele ukuqokelelwa kwetshaja yesithuba, zinciphise ukufakwa kweetshaja zesithuba esifana ne-polarity, kwaye zithintele ukuveliswa kweetshaja zesithuba esingafaniyo ne-polarity ukuthintela ukuphazamiseka kwentsimi yombane ngaphakathi kwe-insulation kunye ne-interfaces, ukuqinisekisa amandla okuqhekeka angachaphazelekiyo kunye nobomi bentambo.

Xa iintambo ze-DC zihlala kwindawo yombane e-unipolar ixesha elide, ii-electron, ii-ion, kunye ne-ionization yokungcola eveliswa kwizinto ze-electrode ngaphakathi kwe-insulation ziba ziindleko zesithuba. Ezi ntlawulo ziyafuduka ngokukhawuleza kwaye ziqokeleleke kwiipakethi zetshaja, ezaziwa ngokuba yi-accumulation of space charge. Ke ngoko, xa kusetyenziswa i-PP kwiintambo ze-DC, kufuneka utshintsho ukuze kuthintelwe ukuveliswa kwetshaja kunye nokuqokelelana kwayo.

4. Ukuqhuba Ubushushu

Ngenxa yokungasebenzi kakuhle kobushushu, ubushushu obuveliswa ngexesha lokusebenza kweentambo ze-DC ezisekwe kwi-PP abunakuphela ngokukhawuleza, nto leyo ebangela umahluko kubushushu phakathi kwamacala angaphakathi nangaphandle komaleko wokugquma, nto leyo edala intsimi yobushushu engalinganiyo. Ukuqhuba kombane kwezinto zepolymer kuyakhula ngokunyuka kwamaqondo obushushu. Ke ngoko, icala langaphandle komaleko wokugquma one-conductivity ephantsi liba sengozini yokuqokelelana kweetshaja, nto leyo ekhokelela ekunciphiseni amandla entsimi yombane. Ngaphezu koko, ii-gradients zobushushu zibangela ukufakwa kunye nokufuduka kwenani elikhulu leetshaja zesithuba, nto leyo ephazamisana ngakumbi nentsimi yombane. Okukhona i-gradient yobushushu inkulu, kokukhona i-gradient yobushushu ikhula, nto leyo eqinisa ukuphambuka kwentsimi yombane. Njengoko kuxoxiwe ngaphambili, ubushushu obuphezulu, ukuqokelelwa kweetshaja zesithuba, kunye nokuphambuka kwentsimi yombane kuchaphazela ubomi obuqhelekileyo bokusebenza kunye nobomi benkonzo yeentambo ze-DC. Ke ngoko, ukuphucula ukuqhutywa kobushushu kwe-PP kuyimfuneko ukuqinisekisa ukusebenza okukhuselekileyo kunye nobomi benkonzo obude beentambo ze-DC.

Ixesha leposi: Jan-04-2024