Isishwankathelo: Umgaqo wokudibanisa, ukwahlulahlula, ukwakheka, inkqubo kunye nezixhobo zezinto zokukhusela i-polyethylene ezidityaniswe ne-silane zentambo kunye neentambo zichazwe ngokufutshane, kwaye ezinye iimpawu zezinto zokukhusela i-polyethylene ezidityaniswe ne-silane ngokwendalo ekusetyenzisweni nasekusetyenzisweni kunye nezinto ezichaphazela imeko yokudibanisa kwezinto ziyaziswa.

Amagama angundoqo: Ukudibanisa i-Silane; Ukudibanisa kwendalo; I-Polyethylene; Ukuvala ubushushu; Ucingo kunye nentambo

Izinto zentambo ze-polyethylene ezidityaniswe ne-silane ngoku zisetyenziswa kakhulu kushishino lweentambo kunye neentambo njengezinto zokukhusela iintambo zamandla ezisebenzisa umbane ophantsi. Izinto ezisetyenziswa ekuvelisweni kweentambo kunye neentambo ezidityaniswe ne-peroxide, kunye ne-cross-linking kunye ne-irradiation cross-linking xa kuthelekiswa nezixhobo zokuvelisa ezifunekayo zilula, kulula ukuzisebenzisa, zixabiso eliphantsi kunye nezinye izibonelelo, ziye zaba zezona zinto ziphambili kwiintambo ezidityaniswe ne-low-voltage ezine-insulation.

1. Umgaqo wokudibanisa intambo edibeneyo yeSilane

Kukho iinkqubo ezimbini eziphambili ezibandakanyekayo ekwenzeni i-silane cross-linked polyethylene: ukufakelwa kunye nokudibanisa. Kwinkqubo yokufakelwa, i-polymer ilahlekelwa yi-H-atom yayo kwi-atom yekhabhoni yesithathu phantsi kwesenzo se-free initiator kunye ne-pyrolysis ibe yi-free radicals, ephendula neqela le- – CH = CH2 le-vinyl silane ukuvelisa i-polymer edityanisiweyo equlethe iqela le-trioxysilyl ester. Kwinkqubo yokudibanisa, i-graft polymer iqala ngokufakelwa i-hydrolyzed xa kukho amanzi ukuvelisa i-silanol, kwaye i- – OH ihlangana neqela le-Si-OH elikufutshane ukuze lenze i-Si-O-Si bond, ngaloo ndlela idibanisa ii-macromolecules ze-polymer.

2. Izinto zekhebula ezidityaniswe nge-Silane kunye nendlela yazo yokuvelisa ikhebula

Njengoko usazi, kukho iindlela zokuvelisa ezinenyathelo eli-2 kunye nenyathelo elinye zeentambo ezidityaniswe nge-silane kunye neentambo zazo. Umahluko phakathi kwendlela enenyathelo eli-2 kunye nendlela enenyathelo eli-1 ulele apho inkqubo yokufakelwa kwe-silane iqhutywa khona, inkqubo yokufakelwa kumenzi wezinto zekhebula zendlela enenyathelo eli-2, inkqubo yokufakelwa kwisityalo sokwenza iintambo zendlela enenyathelo eli-1. Izinto zokufakelwa kwe-polyethylene ezine-silane ezinenyathelo eli-2 ezinesabelo esikhulu semarike zenziwe ngezinto ezibizwa ngokuba zizinto ze-A kunye ne-B, apho izinto ze-A ziyi-polyethylene edityaniswe ngezinto ze-silane kunye ne-B ziyi-catalyst master batch. I-insulating core emva koko idityaniswe emanzini afudumeleyo okanye ngomphunga.

Kukho olunye uhlobo lwe-silane enamanyathelo amabini e-cross-linked polyethylene insulator, apho izinto ze-A ziveliswa ngendlela eyahlukileyo, ngokungenisa i-vinyl silane ngqo kwi-polyethylene ngexesha lokwenziwa ukuze kufunyanwe i-polyethylene enemixokelelwane enamasebe e-silane.

Indlela yenyathelo elinye ikwaneendidi ezimbini, inkqubo yesiqhelo yenyathelo elinye kukusetyenziswa kwezixhobo ezahlukeneyo ngokwendlela yefomula kumlinganiselo wenkqubo yokulinganisa ngokuchanekileyo ekhethekileyo, ibe yi-extruder ekhethekileyo eyenzelwe ngokukodwa kwinqanaba elinye ukugqiba ukufakelwa kunye nokukhutshwa kwesiseko sokufakelwa kwentambo, kule nkqubo, akukho granulation, akukho mfuneko yokuba isityalo sezixhobo zentambo sithathe inxaxheba, yifektri yentambo igqitywe yodwa. Le teknoloji yemveliso yentambo ye-silane edibeneyo kunye ne-formulation ithathwa kakhulu kwamanye amazwe kwaye ibiza kakhulu.

Olunye uhlobo lwezinto zokwambathisa i-silane ezine-cross-linked polyethylene ezidityaniswe ne-silane ezine-step-one zenziwa ngabavelisi bezinto zekhebula, zonke zizinto ezikrwada ngokwefomula kumlinganiselo wendlela ekhethekileyo yokuxuba kunye, ukupakishwa kunye nokuthengiswa, akukho zinto ze-A kunye nezinto ze-B, isityalo sekhebula sinokuba ngqo kwi-extruder ukuze sigqibezele inyathelo ngaxeshanye ukuxhunyelelwa kunye nokukhupha i-cable insulation core. Uphawu olukhethekileyo lwale ndlela kukuba akukho mfuneko yezinto ezikhethekileyo ezibizayo, njengoko inkqubo yokwambathisa i-silane ingagqitywa kwi-extruder eqhelekileyo ye-PVC, kwaye indlela yezinyathelo ezimbini isusa isidingo sokuxuba izinto ze-A kunye ne-B ngaphambi kokukhupha.

3. Ukwakheka kwefomyula

Indlela yokwenziwa kwezinto zekhebula ze-silane cross-linked polyethylene yenziwe ngokubanzi nge-base material resin, i-initiator, i-silane, i-antioxidant, i-polymerization inhibitor, i-catalyst, njl.

(1) I-base resin ngokubanzi yi-low density polyethylene (LDPE) resin ene-melt index (MI) ye-2, kodwa kutshanje, ngophuhliso lwetekhnoloji ye-synthetic resin kunye noxinzelelo lweendleko, i-linear low density polyethylene (LLDPE) nayo isetyenzisiwe okanye isetyenziswa ngokuyinxenye njenge-base resin yale nto. Ii-resin ezahlukeneyo zihlala zinempembelelo enkulu ekufakeni nasekudibaniseni ngenxa yokwahluka kwisakhiwo sazo sangaphakathi se-macromolecular, ngoko ke ukwakheka kuya kuguqulwa ngokusebenzisa ii-base resin ezahlukeneyo okanye uhlobo olufanayo lwe-resin oluvela kubavelisi abahlukeneyo.

(2) Isiqalisi esisetyenziswa kakhulu yi-diisopropyl peroxide (DCP), into ephambili kukuqonda ubungakanani bengxaki, ukuba incinci kakhulu ukubangela ukufakelwa kwe-silane akwanelanga; ukuba ininzi kakhulu ukubangela i-polyethylene cross-linking, nto leyo enciphisa ukunyibilika kwayo, umphezulu we-extruded insulation core urhabaxa, kunzima ukuyicinezela inkqubo. Njengoko ubungakanani besiqalisi esongeziweyo buncinci kakhulu kwaye bunobuthathaka, kubalulekile ukuba sisasazwe ngokulinganayo, ngoko ke ngokubanzi songezwa kunye ne-silane.

(3) I-Silane isetyenziswa ngokubanzi njenge-vinyl unsaturated silane, kuquka i-vinyl trimethoxysilane (A2171) kunye ne-vinyl triethoxysilane (A2151), ngenxa yesantya se-hydrolysis esikhawulezayo se-A2171, ngoko ke khetha abantu abaninzi be-A2171. Ngokufanayo, kukho ingxaki yokongeza i-silane, abavelisi bezixhobo zekhebula zangoku bazama ukufikelela kumda wabo ophantsi wokunciphisa iindleko, kuba i-silane ingeniswa kwamanye amazwe, ixabiso libiza kakhulu.

(4) I-Anti-oxidant kukuqinisekisa uzinzo lwe-polyethylene processing kunye ne-cable anti-aging kunye ne-anti-oxidant eyongeziweyo, i-anti-oxidant kwinkqubo ye-silane grafting inendima yokuthintela i-grafting reaction, ngoko ke inkqubo ye-grafting, ukongezwa kwe-anti-oxidant kufuneka kuqatshelwe, ubungakanani obongeziweyo buqwalaselwe ubungakanani be-DCP ukuze buhambelane nokukhethwa. Kwinkqubo ye-cross-linking enamanyathelo amabini, uninzi lwe-antioxidant lunokongezwa kwi-catalyst master batch, enokunciphisa impembelelo kwinkqubo ye-grafting. Kwinkqubo ye-cross-linking enamanyathelo elinye, i-antioxidant ikhona kuyo yonke inkqubo ye-grafting, ngoko ke ukukhetha uhlobo kunye nobungakanani kubaluleke ngakumbi. Ii-antioxidants ezisetyenziswa rhoqo yi-1010, 168, 330, njl.

(5) I-polymerization inhibitor yongezwa ukuze kuthintelwe ezinye iinkqubo zokufakelwa kunye nenkqubo yokudibanisa i-cross-linking yeziphumo ebezingalindelekanga, kwinkqubo yokudibanisa i-arhente yokudibanisa i-anti-cross-linking, inokunciphisa ngempumelelo ukwenzeka kwe-C2C cross-linking, ngaloo ndlela iphucula ukugeleza kokucubungula, ukongeza, ukongezwa kwe-graft kwiimeko ezifanayo kuya kwandulelwa yi-hydrolysis ye-silane kwi-polymerization inhibitor inokunciphisa i-hydrolysis ye-polyethylene edityanisiweyo, ukuphucula uzinzo lwexesha elide lwezinto zokudibanisa.

(6) IiCatalysts zihlala zizinto eziphuma kwi-organotin (ngaphandle kwe-natural crosslinking), eyona ixhaphakileyo yi-dibutyltin dilaurate (DBDTL), edla ngokufakwa kwimo ye-masterbatch. Kwinkqubo enamanyathelo amabini, i-graft (izinto ze-A) kunye ne-catalyst master batch (izinto ze-B) zipakishwa ngokwahlukeneyo kwaye izinto ze-A kunye ne-B zixutywa kunye ngaphambi kokuba zongezwe kwi-extruder ukuthintela ukudibana kwangaphambili kwezinto ze-A. Kwimeko ye-single-step silane cross-linked polyethylene insulation, i-polyethylene ekwiphakheji ayikafakwa, ngoko ke akukho ngxaki yokudibanisa kwangaphambili kwaye ke ngoko i-catalyst ayifuni ukuhlanganiswa ngokwahlukileyo.

Ukongeza, kukho ii-silane ezidityanisiweyo ezifumanekayo kwimarike, eziyindibaniselwano ye-silane, i-initiator, i-antioxidant, ezinye izinto zokuthambisa kunye nee-anti-copper agents, kwaye zihlala zisetyenziswa kwiindlela zokudibanisa i-silane ezinenyathelo elinye kwizityalo zekhebula.

Ngoko ke, ukwenziwa kwe-silane cross-linked polyethylene insulation, ukwakheka kwayo okungathathwa njengokunzima kakhulu kwaye kufumaneka kulwazi olufanelekileyo, kodwa ukwenziwa kwemveliso efanelekileyo, kuxhomekeke kuhlengahlengiso oluthile ukuze kugqitywe, olufuna ukuqonda ngokupheleleyo indima yamacandelo kwifomyula kunye nomthetho wempembelelo yawo ekusebenzeni kunye nempembelelo yawo efanayo.

Kwiintlobo ngeentlobo zezinto zekhebula, izinto zekhebula ezidityaniswe nge-silane (nokuba zinyathelo ezimbini okanye inyathelo elinye) zithathwa njengezona kuphela iintlobo zeenkqubo zeekhemikhali ezenzeka kwi-extrusion, ezinye iintlobo ezifana nezinto zekhebula ze-polyvinyl chloride (PVC) kunye nezinto zekhebula ze-polyethylene (PE), inkqubo ye-extrusion granulation yinkqubo yokuxuba ebonakalayo, nokuba izinto zekhebula ezidityaniswe nge-chemical cross-linking kunye ne-irradiation, nokuba zikwinkqubo ye-extrusion granulation, okanye kwinkqubo ye-extrusion Cable, akukho nkqubo yekhemikhali eyenzekayo, ngoko ke, xa kuthelekiswa, ukuveliswa kwezinto zekhebula ezidityaniswe nge-silane kunye ne-extrusion ye-cable insulation, ulawulo lwenkqubo lubaluleke ngakumbi.

4. Inkqubo yokuvelisa i-silane ene-cross-linked polyethylene insulation enezinyathelo ezimbini

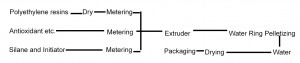

Inkqubo yokuvelisa i-silane enamanyathelo amabini e-cross-linked polyethylene insulation A material ingamelwa ngokufutshane nguMfanekiso 1.

Umfanekiso 1 Inkqubo yokuvelisa izinto zokukhusela i-silane ezineenyathelo ezimbini ezidityaniswe ne-polyethylene A

Amanye amanqaku aphambili kwinkqubo yokuvelisa i-silane enamanyathelo amabini e-cross-linked polyethylene insulation:

(1) Ukomisa. Njengoko i-polyethylene resin inamanzi amancinci, xa ikhutshwa kumaqondo obushushu aphezulu, amanzi asabela ngokukhawuleza kunye namaqela e-silyl ukuze avelise i-cross-linking, nto leyo enciphisa ukunyibilika kwe-melt kwaye ivelise i-pre-cross-linking. Izinto ezigqityiweyo zikwanamanzi emva kokuba amanzi epholile, nto leyo enokubangela i-pre-crosslinking ukuba ayisuswanga, kwaye kufuneka yomiswe. Ukuqinisekisa umgangatho wokomisa, kusetyenziswa iyunithi yokomisa enzulu.

(2) Ukulinganisa. Njengoko ukuchaneka kokwenziwa kwezinto kubalulekile, kusetyenziswa isikali sokulinganisa esingeniswayo esinobunzima. I-resin ye-polyethylene kunye ne-antioxidant zilinganiswa kwaye zondliwa nge-feed port ye-extruder, ngelixa i-silane kunye ne-initiator zifakwa yipompo yezinto ezingamanzi kwibharele yesibini okanye yesithathu ye-extruder.

(3) Ukufakelwa kwe-Extrusion. Inkqubo yokufakelwa kwe-silane igqitywa kwi-extruder. Useto lwenkqubo ye-extruder, kubandakanya ubushushu, indibaniselwano ye-screw, isantya se-screw kunye nesantya sokutya, kufuneka ilandele umgaqo wokuba izinto ezikwicandelo lokuqala le-extruder zinokunyibilika ngokupheleleyo kwaye zixutywe ngokulinganayo, xa ukubola kwangaphambi kwexesha kwe-peroxide kungafuneki, kwaye izinto ezikwicandelo lesibini le-extruder kufuneka zibole ngokupheleleyo kwaye inkqubo yokufakelwa igqitywe. Ubushushu obuqhelekileyo becandelo le-extruder (LDPE) buboniswe kwiTheyibhile 1.

Itheyibhile 1 Amaqondo obushushu eendawo zokukhupha izinto ezinamanyathelo amabini

| Indawo yokusebenza | Indawo 1 | Indawo yesi-2 | Indawo 3 ① | Indawo 4 | Indawo 5 |

| Ubushushu P °C | 140 | 145 | 120 | 160 | 170 |

| Indawo yokusebenza | Indawo 6 | Indawo 7 | Indawo 8 | Indawo 9 | Umlomo ufa |

| Ubushushu °C | 180 | 190 | 195 | 205 | 195 |

Kulapho kongezwa khona i-silane.

Isantya sesikrufu se-extruder simisela ixesha lokuhlala kunye nesiphumo sokuxuba sezinto ezikwi-extruder, ukuba ixesha lokuhlala lifutshane, ukubola kwe-peroxide akuphelelanga; ukuba ixesha lokuhlala lide kakhulu, i-viscosity yezinto ezikhutshiweyo iyanda. Ngokubanzi, ixesha eliqhelekileyo lokuhlala le-granule kwi-extruder kufuneka lilawulwe kwixesha lokubola kwe-initiator le-half-life le-5-10. Isantya sokutya asinayo kuphela impembelelo ethile kwixesha lokuhlala lezinto, kodwa nakwi-mixing and shearing of the material, ukukhetha isantya sokutya esifanelekileyo nako kubaluleke kakhulu.

(4) Ukupakisha. Izinto zokukhusela ezidityaniswe ne-silane ezinamanyathelo amabini kufuneka zipakishwe kwiingxowa ze-aluminium-plastiki ezidityanisiweyo emoyeni ngqo ukuze kususwe umswakama.

5. Inkqubo yokuvelisa izinto zokukhusela i-silane edityaniswe ne-polyethylene enenyathelo elinye

Izinto zokugquma ze-polyethylene ezine-silane cross-linked polyethylene ngenxa yenkqubo yazo yokugquma zikwi-extrusion yefektri ye-cable factory ye-cable insulation core, ngoko ke ubushushu be-extrusion ye-cable insulation buphezulu kakhulu kunendlela ye-two-step. Nangona ifomula ye-polyethylene ene-silane cross-linked polyethylene iqwalaselwe ngokupheleleyo ekusasazekeni ngokukhawuleza kwe-initiator kunye ne-silane kunye ne-material shear, kodwa inkqubo yokugquma kufuneka iqinisekiswe bubushushu, obuyi-single-step silane cross-linked polyethylene insulation production plant igxininise ngokuphindaphindiweyo ukubaluleka kokukhetha ubushushu be-extrusion ngokuchanekileyo, ubushushu be-extrusion obucetyiswayo ngokubanzi buboniswe kwiTheyibhile 2.

Itheyibhile 2 Ubushushu bomkhupheli wenyathelo elinye wezoni nganye (iyunithi: ℃)

| Indawo | Indawo 1 | Indawo yesi-2 | Indawo 3 | Indawo 4 | Iflengi | Intloko |

| Ubushushu | 160 | 190 | 200~210 | 220~230 | 230 | 230 |

Le yenye yeengxaki zenkqubo ye-polyethylene edityaniswe ne-silane enenyathelo elinye, engafunekiyo xa kukhutshwa iintambo ngamanyathelo amabini.

6. Izixhobo zemveliso

Izixhobo zemveliso zisisiqinisekiso esibalulekileyo solawulo lwenkqubo. Ukuveliswa kweentambo ezidityaniswe nge-silane kufuna izinga eliphezulu kakhulu lokuchaneka kolawulo lwenkqubo, ngoko ke ukukhetha izixhobo zemveliso kubaluleke kakhulu.

Ukuveliswa kwezinto zokugquma ze-silane ezine-cross-linked polyethylene ezisebenzisa i-silane cross-linked. Izixhobo zokuvelisa izinto, okwangoku zisetyenziswa njenge-extruder ye-isotropic parallel twin-screw extruder yasekhaya enobunzima obungenabunzima obungeniswayo, izixhobo ezinjalo zinokuhlangabezana neemfuno zokuchaneka kolawulo lwenkqubo, ukukhetha ubude kunye nobubanzi be-extruder ye-twin-screw ukuqinisekisa ukuba ixesha lokuhlala kwezinto lihlala, ukukhetha ubunzima obungenabunzima obungeniswayo ukuqinisekisa ukuchaneka kwezithako. Kakade ke, zininzi iinkcukacha zezixhobo ekufuneka zinikwe ingqalelo epheleleyo.

Njengoko bekutshiwo ngaphambili, izixhobo zokuvelisa intambo ezidityaniswe nge-silane enye kwisityalo sentambo zingeniswa kwamanye amazwe, zibiza kakhulu, abavelisi bezixhobo zasekhaya abanazo izixhobo zokuvelisa ezifanayo, isizathu kukungabikho kwentsebenziswano phakathi kwabavelisi bezixhobo kunye nabaphandi befomula kunye neenkqubo.

7. Izinto zokwambathisa ze-polyethylene ezidityaniswe nge-Silane yendalo

Izinto zokukhusela i-polyethylene ezidityaniswe ne-silane yendalo eziphuhliswe kwiminyaka yakutshanje zinokudityaniswe phantsi kweemeko zendalo kwiintsuku ezimbalwa, ngaphandle kokuntywiliselwa ngomphunga okanye emanzini afudumeleyo. Xa kuthelekiswa nendlela yendabuko yokudibanisa i-silane, ezi zinto zinokunciphisa inkqubo yemveliso yabavelisi beentambo, zinciphise iindleko zemveliso kwaye zonyuse ukusebenza kakuhle kwemveliso. Ukufakwa kwe-polyethylene okudityaniswe ne-silane ngokwemvelo kuqatshelwa kwaye kusetyenziswa ngabavelisi beentambo.

Kwiminyaka yakutshanje, i-silane yasekhaya ene-cross-linked polyethylene insulation iye yavuthwa kwaye iveliswa ngobuninzi, kunye neenzuzo ezithile ngexabiso xa kuthelekiswa nezinto ezivela kwamanye amazwe.

7. 1 Iingcamango zokwenza izinto zokukhusela i-silane ezidityaniswe ngokwendalo kunye ne-polyethylene

Ii-insulation ze-polyethylene ezidityaniswe ne-silane natural cross-linked polyethylene ziveliswa ngenkqubo enamanyathelo amabini, kunye nefomyula efanayo equka i-base resin, i-initiator, i-silane, i-antioxidant, i-polymerisation inhibitor kunye ne-catalyst. Ukwenziwa kwee-insulators ze-polyethylene ezidityaniswe ne-silane natural cross-linked polyethylene kusekelwe ekwandiseni izinga lokufakelwa kwe-silane lezinto ze-A kunye nokukhetha i-catalyst esebenza ngcono kune-silane water warm-linked polyethylene insulators. Ukusetyenziswa kwezinto ze-A ezinezinga eliphezulu lokufakelwa kwe-silane kunye ne-catalyst esebenza ngcono kuya kwenza i-silane cross-linked polyethylene insulator ikwazi ukudibana ngokukhawuleza nokuba kumaqondo obushushu aphantsi kwaye kungekho kufuma okwaneleyo.

Izinto ze-A zezinto ze-silane ezidityaniswe ngokwemvelo ezifakwe kwi-polyethylene zihlanganiswa yi-copolymerisation, apho umxholo we-silane unokulawulwa kwinqanaba eliphezulu, ngelixa ukuveliswa kwezinto ze-A ezinezinga eliphezulu lokuxhunyelelwa ngokuxhunyelelwa kwe-silane kunzima. I-resin esisiseko, i-initiator kunye ne-silane esetyenzisiweyo kwiresiphi kufuneka zahlulwe kwaye zilungiswe ngokweendidi kunye nokudibanisa.

Ukukhethwa kwe-resist kunye nokulungiswa kwedosi yayo nako kubalulekile, njengoko ukonyuka kwesantya sokufakelwa kwe-silane ngokungenakuphepheka kukhokelela kwiimpendulo ezingaphezulu ze-CC crosslinking. Ukuze kuphuculwe ukutyibilika kokucubungula kunye nemeko yomphezulu wezinto ze-A zokukhupha intambo emva koko, kufuneka isixa esifanelekileyo se-polymerization inhibitor ukuze kuthintelwe ngempumelelo i-CC crosslinking kunye ne-pre-crosslinking.

Ukongeza, ii-catalysts zidlala indima ebalulekileyo ekwandiseni izinga lokudibanisa kwaye kufuneka zikhethwe njengee-catalysts ezisebenzayo eziqulethe izinto ezingenasinyithi esiguqukayo.

7. 2 Ixesha lokudibanisa i-silane crosslinked ngokwemvelo polyethylene insulations

Ixesha elifunekayo ukugqiba ukuhlanganiswa kwe-silane natural cross-linked polyethylene insulation kwimeko yayo yendalo lixhomekeke kubushushu, ukufuma kunye nobukhulu bomaleko wokugquma. Okukhona ubushushu kunye nokufuma kuphezulu, kokukhona ubukhulu bomaleko wokugquma buncipha, kokukhona ixesha lokudibanisa lifutshane, kwaye kokukhona lide ngokuchaseneyo. Njengoko ubushushu kunye nokufuma kwahluka ukusuka kummandla ukuya kummandla nakwixesha lonyaka, nokuba kwindawo enye kwaye ngexesha elifanayo, ubushushu kunye nokufuma namhlanje nangomso kuya kwahluka. Ke ngoko, ngexesha lokusetyenziswa kwezinto, umsebenzisi kufuneka amisele ixesha lokudibanisa ngokuhambelana nobushushu kunye nokufuma kwendawo kunye nendawo ekhoyo, kunye nenkcazo yentambo kunye nobukhulu bomaleko wokugquma.

Ixesha lokuthumela: Agasti-13-2022